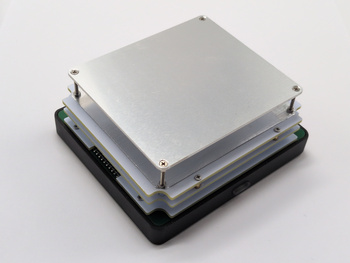

The project Reflow Micro Table has achieved stability, creating an open device for easy and effective soldering using thermal profiles in a home setting. The project aims not only to be practical but also educational, demonstrating to beginners that assembling modern electronics can be accessible to anyone. While devices like MHP50 and HP15 exist on the market, this project offers a unique set of features:

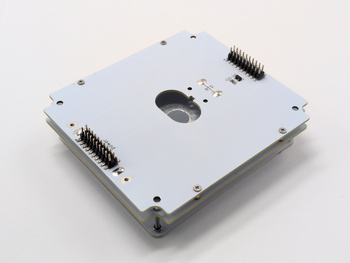

- A larger and more comfortable working area (80x70mm compared to 50x50mm).

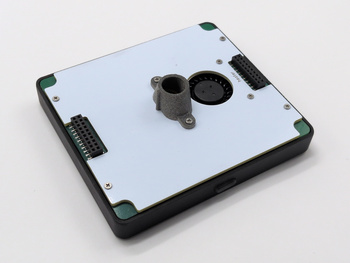

- Control via Bluetooth LE from a web browser with a user-friendly interface.

- Utilizing only technologies that are readily available at home. The most challenging operation is countersinking the 4 heater mounting holes; the rest involves ordering components online and assembly.

Due to technological constraints, the main heater used is an aluminum printed circuit board, limiting the maximum temperature to 180°C. However, this is sufficient for automatic soldering with low-temperature pastes or bottom heating. There is also an experimental heater based on MCH elements that can operate up to 300°C, but it is significantly more costly and not practical for home use. Detailed instructions for assembly are provided, and the web application includes a demo mode for testing the interface without hardware.